SCHAUENBURG Industrietechnik with the VIGOT® brand has made safety its top priority - "Safety first". This includes professionally qualified training in accordance with "Qualified person according to Betr.SichV §2 para. 7 or TRBS 1203". Regular inspections, supported by maintenance contracts, are a prerequisite for the use of hose lines in machinery and contribute to the safety of man and machine, thus minimizing downtimes. The periodic inspections take place on site.

SCHAUENBURG Industrietechnik with the VIGOT® brand has made safety its top priority - "Safety first". This includes professionally qualified training in accordance with "Qualified person according to Betr.SichV §2 para. 7 or TRBS 1203". Regular inspections, supported by maintenance contracts, are a prerequisite for the use of hose lines in machinery and contribute to the safety of man and machine, thus minimizing downtimes. The periodic inspections take place on site.

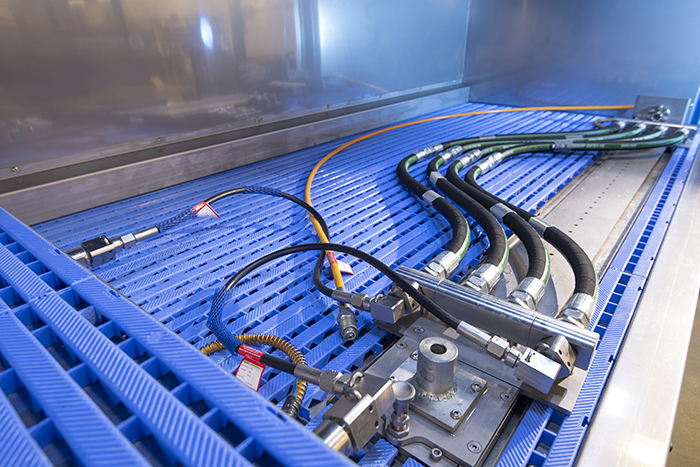

Test center for hose lines

Test center for hose lines

Hose lines that are assembled by us are then inspected in our in-house test center. Here, the hoses are tested in accordance with the requirements at up to 4000 bar. We have an underwater test stand, which is essential for metal hose lines. Our test center offers all the necessary testing options, from underwater leak tests to strength tests up to 4000 bar. The hose lines receive a product passport that accompanies them for the entire service life of the hose and provides transparent documentation for your machinery and employees.

• First-class equipped test center

• First-class equipped test center

• Test pressure certificates up to 4000 bar

• Leak tests with air under water

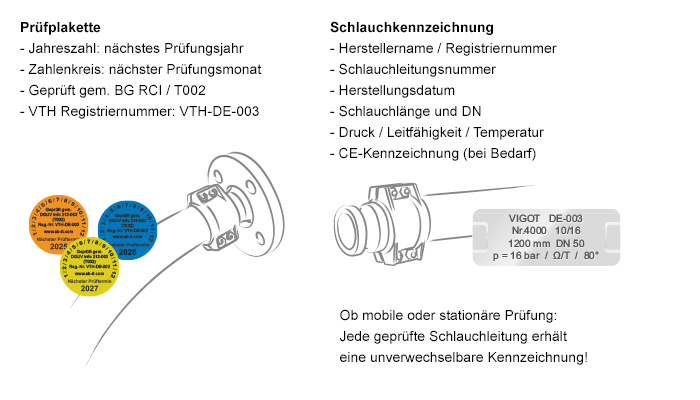

• Unmistakable marking of the products

• Endoscopy and analyses

• Very high testing capacity

Mobile hose testing on site

Mobile hose testing on site

Our on-site testing service, carried out by our specialists, significantly reduces machine downtimes and helps you to fulfill legal obligations smoothly. Regular inspections of your hose lines are prescribed by the manufacturer. For chemical, food, metal and steam hose systems, repeat inspections at fixed intervals similar to a TÜV inspection are mandatory. SCHAUENBURG Industrietechnik specializes in mobile testing and has the know-how, the equipment and, above all, hose specialists with all the necessary approvals and extensive experience!![]()

• Compliance with legal regulations

• Replacement of defective hose lines

• On-site installation service

• Testing at your factory

• Minimization of downtimes

• Advice on hoses and their use

Our additional service: The hose register

Hose lines are recorded in a hose register. This allows you to see historically when which hose was tested. The chronological sequence and lists for upcoming inspections are important components of a smooth and fast inspection. Our service enables you to plan optimally.

With our testing service, you fulfill your responsibilities in the best possible way and make a significant contribution to protecting employees and the environment. Tested and functional hose lines are crucial for the long-term economic operation of your systems.

How to recognize a tested hose line

How to recognize a tested hose line